Full Package

We specialize in knitted fabric production, offering a service that ranges from product development to garment finishing.

We have a team of qualified professionals allowing us to guarantee quality in each process. Our employees have constant training and commitment aimed at satisfying the requirements and needs of our customers.

Manufacturing capacity and strategic alliances are one of the main strengths of the FULL PACKAGE service we offer.

MINIMUM ORDER QUANTITY (MIQ):

- Minimum per fabric: 500 garments

- Minimum per color: 500 garments

- Minimum per style: 250 garments

- Minimum for embroidery, prints and sublimation: 250 garments

DEADLINES

- Quote: 10 days

- Prototype: 10 – 15 days

- Lab Dipping: 10 – 15 días

- Sales Samples: 45 days

- Yield: 45 – 120 days

Processes

COMMERCIAL ADVICE

We can advise them on every step of your production order, from the mold manufacturing process to the total delivery of the product.

Depending on your requirements we can process orders in less time than the market establishes. Despite having procedures, we are able to attend to and resolve any emergency.

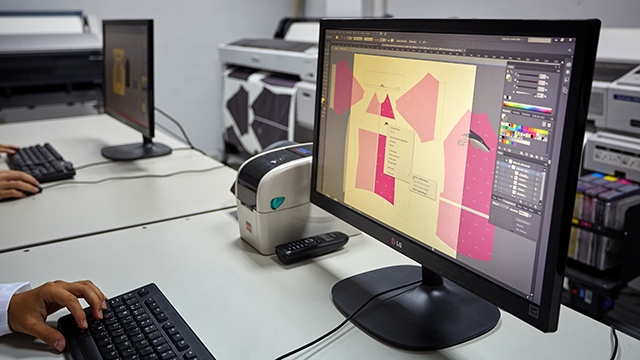

PRODUCT DESIGN AND DEVELOPMENT

We have specialized modelers who master the Audaces System and Lectra use it to make molds, chalks and scales according to the design ideas of our customers. It ranges from mold development, sample making and size scaling. All the processes by which the garment will go through as requested by the client are analyzed and developed.

COURT

The fabric is laid and cut according to the molds and cutting technical specifications. To obtain the cut of the fabric, models of the garment to be made are previously designed with its particularities. It then goes through strict quality control.

SEWING

The cut parts go through an assembly process, according to the specifications of the technical sheet. It includes sewing, remeshing, fastening, buttoning, logos, labeling and other operations to deliver the garment for its final finish. Quality is controlled and inspected throughout the process and is referred to the finishing area.

FINISHING

We proceed with the review of the garments to classify them according to the standards of our customers. Once the garments are enabled, they are sent to steaming-ironing, followed by the placement of labels with relevant information about the product: size, price, style; then the garments go to folding, bagging and lacing respectively. Finally, an audit is carried out to ensure the quality of the office.

QUALITY CONTROL

Quality control consists of the application of mechanisms, actions and tools aimed at detecting errors.

1) Design quality control:

We check that the models to be made are correct to the technical specifications and parameters requested by our customers.