Experience quality

We are a Peruvian company dedicated to the manufacture of high quality garments in knitted and flat fabrics in our exports.

In South America we have customers in Brazil, Colombia, Chile and Venezuela. Central America, Costa Rica and North America to the United States.

In 2018 we made the shirts of the Peruvian national team for the World Cup in Russia for the Umbro brand.

Our commitment is to provide the national and international customer with high quality products complying with all the technical specifications and the required standards, as well as compliance with the established times.

We believe that the spread of respect for rights is a principle that allows the development of human capital. Our responsibility is to promote positive practices that contribute to the well-being of our employees.

MISSION

Work responsibly to deliver high quality products to our customers in the agreed time.

We promote action with social and environmental responsibility.

VISION:

To be recognized as a leading company in clothing manufacturing with international quality with a high level of attention to our customers.

Responsibilityand commitment

Responsibility and commitment: it is based on the fulfillment of functions and activities that involve the development of sustainable products.

Team Integration multidisciplinary

Teamwork: creates a favorable environment for the well-being of the employee and allows the development of their efficiency.

Experience of quality

Quality: to meet the standards required by our customer.

They trust us

Processes

COMMERCIAL ADVICE

We can advise them on every step of your production order, from the mold manufacturing process to the total delivery of the product.

Depending on your requirements we can process orders in less time than the market establishes. Despite having procedures, we are able to attend to and resolve any emergency.

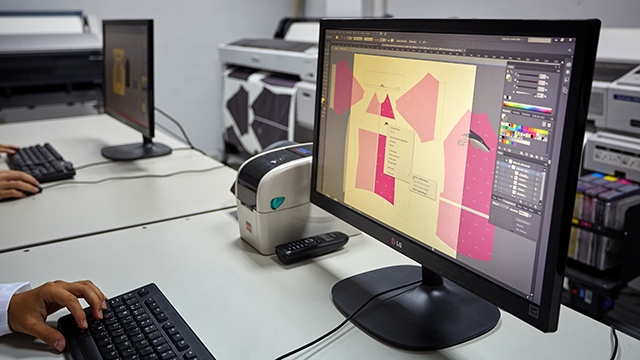

PRODUCT DESIGN AND DEVELOPMENT

We have specialized modelers who master the Audaces System and Lectra use it to make molds, chalks and scales according to the design ideas of our customers. It ranges from mold development, sample making and size scaling. All the processes by which the garment will go through as requested by the client are analyzed and developed.

COURT

The fabric is laid and cut according to the molds and cutting technical specifications. To obtain the cut of the fabric, models of the garment to be made are previously designed with its particularities. It then goes through strict quality control.

SEWING

The cut parts go through an assembly process, according to the specifications of the technical sheet. It includes sewing, remeshing, fastening, buttoning, logos, labeling and other operations to deliver the garment for its final finish. Quality is controlled and inspected throughout the process and is referred to the finishing area.

FINISHING

We proceed with the review of the garments to classify them according to the standards of our customers. Once the garments are enabled, they are sent to steaming-ironing, followed by the placement of labels with relevant information about the product: size, price, style; then the garments go to folding, bagging and lacing respectively. Finally, an audit is carried out to ensure the quality of the office.

QUALITY CONTROL

Quality control consists of the application of mechanisms, actions and tools aimed at detecting errors.

1) Design quality control:

We check that the models to be made are correct to the technical specifications and parameters requested by our customers.

Do you have any questions?

Write to us for our advisors

they can attend to you as soon as possible.